the cap is a rubber piece, that can be removed.

It seal in grease and protect to rotating parts.

The shape is conical, diameter from 22 to 25 mm.

The covered nut has 19mm diameter.

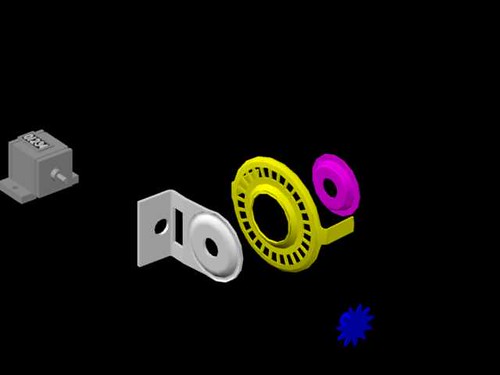

Image without cap.

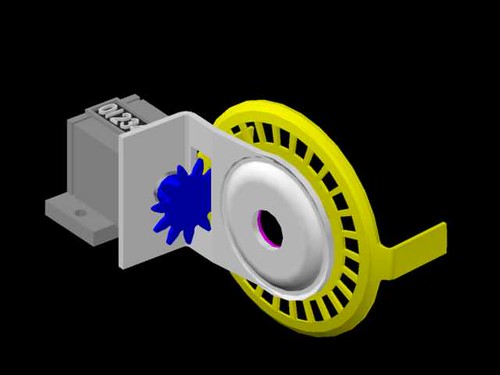

Image with cap.

Sketch of the sectioned hub.

Fabio