When I first started measuring, Pete recommended a 5-digit counter for easier reading and recording. In spite of that, I've still made some transposition errors over the years. I'm sold on 5 digits.

Tom does not plan to attend the USATF Annual Meeting. If a counter exists in time, he will send it to Stu, Course Registrar, who does plan to attend.

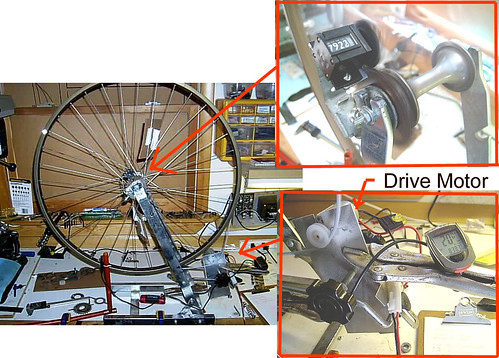

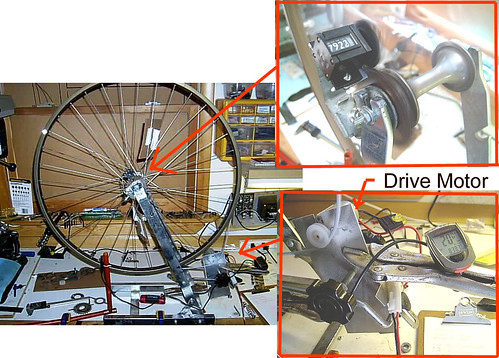

The testing rig is ready to go and we hope to have a video soon.

The testing rig is ready to go and we hope to have a video soon.

I have one more minor modification to incorporate into the final design before I order. I believe the 90 degree bend that forms the shelf the counter mounts to would benefit from a bit of reinforcement. A small crease at a right angle to the bend is all that's needed. I will be drafing this while I run some tests this weekend. More updates to come.

I am told the typical time for shop drawings is 6-8 weeks from the time of order, still a week or two off. This will be cutting it short for the USATF meeting, but I'm hoping to stuff some stockings this Christmas.

I have had considerable difficulty finding suppliers of speedometer cable pieces. I've contacted the primary suppliers, but the fittings are no longer in production thanks to modern electronics. Once the basic counter is in production, I am confident I can adapt it to a cable-driven rig if suitable hardware is found. I've yet to come up with a solution for less than $50 to rig the cable, and that's my break point. The counter reads very well with the proposed mount.

Thanks to all for your input.

Tom Riegel

I am told the typical time for shop drawings is 6-8 weeks from the time of order, still a week or two off. This will be cutting it short for the USATF meeting, but I'm hoping to stuff some stockings this Christmas.

I have had considerable difficulty finding suppliers of speedometer cable pieces. I've contacted the primary suppliers, but the fittings are no longer in production thanks to modern electronics. Once the basic counter is in production, I am confident I can adapt it to a cable-driven rig if suitable hardware is found. I've yet to come up with a solution for less than $50 to rig the cable, and that's my break point. The counter reads very well with the proposed mount.

Thanks to all for your input.

Tom Riegel

Message from Tom Riegel - He has got his test rig built and is checking the running and wear on the gears.

The Test Rig

I'll do a writeup when it's over, but looking good so far. I'm running at 190 rpm at the wheel, and the cyclocomputer makes it right at 20 mph. 9 hours in. I should have caught up to your counter by morning, if I can get any sleep with the thing running. The aluminum plate I used to mount the motor is ringing like a bell. I attached the vice-grips to dampen it, but it isn't exactly 100% effective.

So far, the only sign of wear is very small "leaflets" that grew from the plastic gear teeth at about 5 hours in. They have since worn off, and all is smooth.

More from Tom 29 September

I'm at it again. 350 miles yesterday, I'm shooting for 500. I ended up turning it off at 12:30 AM to get some sleep. It's so noisy, I'm hesitant to even move it outside. If the test goes longer (and it may for the final rig) I'll move it into the cabana (Tom's backyard toolshed). Think of an electric drill running, that's about what I'm dealing with.

Only very minor wear on the plastic gear, still no additional wobble on the metal one. No lube at all. I'll dis-assemble it and re-measure the inner diameter at the end. It started at 24.75mm for the hole, 24.65+/- on the retainer cup.

I'm short on time at the moment to get the production docs together for the fabricator, but I think I can get something together by next (not this) Monday. The 3D rendering is fine, but I'll need orthogonal views that call-out the specifics, and where they can take liberties.

While I think I want to keep the name "Jones counter", "the totalizer" has a nice ring to it.

I gotta go outside, this thing is driving me mad.

The Test Rig

I'll do a writeup when it's over, but looking good so far. I'm running at 190 rpm at the wheel, and the cyclocomputer makes it right at 20 mph. 9 hours in. I should have caught up to your counter by morning, if I can get any sleep with the thing running. The aluminum plate I used to mount the motor is ringing like a bell. I attached the vice-grips to dampen it, but it isn't exactly 100% effective.

So far, the only sign of wear is very small "leaflets" that grew from the plastic gear teeth at about 5 hours in. They have since worn off, and all is smooth.

More from Tom 29 September

I'm at it again. 350 miles yesterday, I'm shooting for 500. I ended up turning it off at 12:30 AM to get some sleep. It's so noisy, I'm hesitant to even move it outside. If the test goes longer (and it may for the final rig) I'll move it into the cabana (Tom's backyard toolshed). Think of an electric drill running, that's about what I'm dealing with.

Only very minor wear on the plastic gear, still no additional wobble on the metal one. No lube at all. I'll dis-assemble it and re-measure the inner diameter at the end. It started at 24.75mm for the hole, 24.65+/- on the retainer cup.

I'm short on time at the moment to get the production docs together for the fabricator, but I think I can get something together by next (not this) Monday. The 3D rendering is fine, but I'll need orthogonal views that call-out the specifics, and where they can take liberties.

While I think I want to keep the name "Jones counter", "the totalizer" has a nice ring to it.

I gotta go outside, this thing is driving me mad.

quote:Jones-n-Riegel Count-n-Thingel

A name with a flourish!

I much prefer the 6-digit, as I do longer courses regularly. I co-measure with someone handicapped with a 5-digit. When entering into my Excel spreadsheet, I have to make sure I keep the increments proper, as the 5-digit rolls-over. Not a huge issue, but automation is done for a reason.

I have not had an issue with transposing numbers while using the 6-digit. So, my vote (and my orders to Paul reflect) is for a 6-digit. I would be a screamin' mimi if a 6-digit is not offered. Simplicity is served by not having to remember to add digits when more than 100,000 counts are needed for a course.

My 2-cents worth,

Duane

So the tones of the Jones are ringing through your bones?

Have to admit I like the J-R idea, but Count-n-Thingel has a nice ring (so to speak) to it.

Have to admit I like the J-R idea, but Count-n-Thingel has a nice ring (so to speak) to it.

I finished a 500 mile test at 20 mph, and it went pretty much as I hoped. Minor wear on the plastic gear teeth, the metal ring gear, and the retainer cup were observed.

The retainer cup was seen to wear approximately 0.10 mm as the ring gear cut a groove into it, finishing at 24.55+/- 0.02mm.

Interesting enough to note, the ring gear grew by 0.03mm, finishing with an inside diameter of 24.72mm +/- 0.01 mm. The inner rim formed a sharp edge along the inside that can just be felt with the fingers. The root diameter remained a constant 24.75mm, measured opposite the sharp edge. Minor abrasion on the sides was barely able to remove the surface rust, and depth of wear is on the order of 0.02mm at the most.

The plastic gear held up very well, and a small, polished indent formed on the face of the teeth approximately 3mm wide, and 0.25mm deep. The width of wear is due to the slight wobble as the ring gear (made from 0.75mm, or 0.032" steel) rotates. The "leaflets" that grew were easily brushed off, and had the consistency of grease when rolled in the fingers.

No observable difference in the counter itself was noted before and after the test. Veeder-Root makes a fine counter.

The unit operated with little noise (aside from the drive motor) and no heat buildup during the test.

I've put the finishing touches on the 3D model, and have started the working documents for production.

Best,

Tom

The retainer cup was seen to wear approximately 0.10 mm as the ring gear cut a groove into it, finishing at 24.55+/- 0.02mm.

Interesting enough to note, the ring gear grew by 0.03mm, finishing with an inside diameter of 24.72mm +/- 0.01 mm. The inner rim formed a sharp edge along the inside that can just be felt with the fingers. The root diameter remained a constant 24.75mm, measured opposite the sharp edge. Minor abrasion on the sides was barely able to remove the surface rust, and depth of wear is on the order of 0.02mm at the most.

The plastic gear held up very well, and a small, polished indent formed on the face of the teeth approximately 3mm wide, and 0.25mm deep. The width of wear is due to the slight wobble as the ring gear (made from 0.75mm, or 0.032" steel) rotates. The "leaflets" that grew were easily brushed off, and had the consistency of grease when rolled in the fingers.

No observable difference in the counter itself was noted before and after the test. Veeder-Root makes a fine counter.

The unit operated with little noise (aside from the drive motor) and no heat buildup during the test.

I've put the finishing touches on the 3D model, and have started the working documents for production.

Best,

Tom

Tom,

The RRTC thanks you for your time and expertise. I am looking forward to making my purchase as soon as you say it's ready.

Best regards,

Gene

P.S.

The RRTC thanks you for your time and expertise. I am looking forward to making my purchase as soon as you say it's ready.

Best regards,

Gene

P.S.

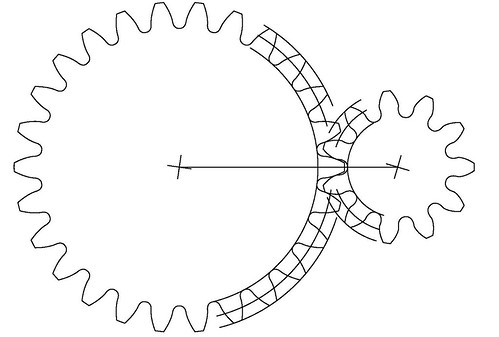

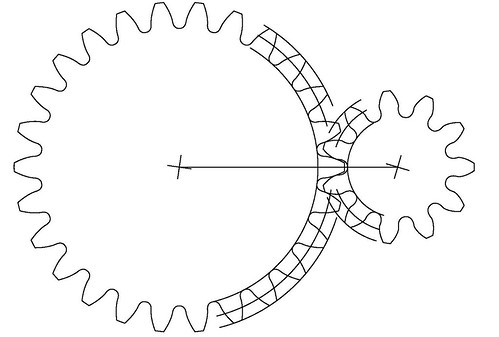

More Progress from Tom

Truly generated involute gears, 20 degree pressure angle, module of 2.5mm, the works. I got a little help on the CAD forum. These will mate nicely in the final assembly.

I finished the cross-section details last night, but left them at home.

More to come.

Truly generated involute gears, 20 degree pressure angle, module of 2.5mm, the works. I got a little help on the CAD forum. These will mate nicely in the final assembly.

I finished the cross-section details last night, but left them at home.

More to come.

I am desperately trying to find counters for my measurement.

I tryed to contact Laurent Lacroix but he told me that he his waiting for some parts and suggested to contact Pete and Tom Riegel.

Does any of you guys the chance to send me over to Europe some counters.

Thanks

I tryed to contact Laurent Lacroix but he told me that he his waiting for some parts and suggested to contact Pete and Tom Riegel.

Does any of you guys the chance to send me over to Europe some counters.

Thanks

WORK REMAINING TO BE DONE

Tom has a design almost ready to be sent to the fabricator. It is slightly different from the design previously submitted. The tooling cost for the earlier design is OK. When the new design is submitted we will receive a new tooling proposal, and a cost for punching and assembling gear drives. We expect to submit the new design in a week or two.

If the costs are comparable to those previously received we will order a number of gear assemblies. It will take about two months for the assemblies to be fabricated and delivered.

We have obtained a domain name and are building a web page from which the counters can be ordered. While we are waiting for gears to be delivered we will finalize the web page design. Tom will also order a number of plastic gears (probably delrin), and a supply of Veeder-Root counters. When the gear drives are received the counters will be mounted to the drives by Tom.

Method of payment can be handled in two ways. A dollar check on a US bank, or a money order that will be accepted without a surcharge will be one method. A second method will be a valid credit card number. Payment must be received in advance. Sad experience has shown that this must be done. Some customers have been in a great hurry to receive their counters, but have lost their sense of urgency when it is time to pay.

If all goes well the name of the web page will be published in three months or so. This is not a promise – it is simply an estimate. The cost of tooling requires that we get it right the first time.

I am not sure whether Paul Oerth is still selling the counters with the plastic gearbox. Those who are desperate can try him.

Tom has a design almost ready to be sent to the fabricator. It is slightly different from the design previously submitted. The tooling cost for the earlier design is OK. When the new design is submitted we will receive a new tooling proposal, and a cost for punching and assembling gear drives. We expect to submit the new design in a week or two.

If the costs are comparable to those previously received we will order a number of gear assemblies. It will take about two months for the assemblies to be fabricated and delivered.

We have obtained a domain name and are building a web page from which the counters can be ordered. While we are waiting for gears to be delivered we will finalize the web page design. Tom will also order a number of plastic gears (probably delrin), and a supply of Veeder-Root counters. When the gear drives are received the counters will be mounted to the drives by Tom.

Method of payment can be handled in two ways. A dollar check on a US bank, or a money order that will be accepted without a surcharge will be one method. A second method will be a valid credit card number. Payment must be received in advance. Sad experience has shown that this must be done. Some customers have been in a great hurry to receive their counters, but have lost their sense of urgency when it is time to pay.

If all goes well the name of the web page will be published in three months or so. This is not a promise – it is simply an estimate. The cost of tooling requires that we get it right the first time.

I am not sure whether Paul Oerth is still selling the counters with the plastic gearbox. Those who are desperate can try him.

You might consider signing up for PayPal and using that on the site. One advantage of PayPal is its automatic currency conversion, so foreign buyers don't have to muck about with getting a check made out in dollars.

PayPal takes 3-4% for their trouble, so you may want to build that into your costs. It's a great convenience for buyers and sellers. At least, for those with PayPal accounts.

PayPal takes 3-4% for their trouble, so you may want to build that into your costs. It's a great convenience for buyers and sellers. At least, for those with PayPal accounts.

I would like only to suggest you to take in conideration also the way the new counter will be mounted on the wheel spindel.

I say this because I had some trouble to find how to mount my actual JOL counter on a bike, I was able to do it only with the 3th bike I tried and after modifing a little the gear hole (enlarged).

The first 2 bikes was a Cannondale Road Bike and a Cannondale MTB, where it was impossible to mount.

Regards,

Fabio

I say this because I had some trouble to find how to mount my actual JOL counter on a bike, I was able to do it only with the 3th bike I tried and after modifing a little the gear hole (enlarged).

The first 2 bikes was a Cannondale Road Bike and a Cannondale MTB, where it was impossible to mount.

Regards,

Fabio

Look at the JO counter shown at the heading of this page. The new counter (tentatively called "Jones Counter model JR") has the same mounting geometry.

Recent JO counters have a plastic gearbox. The geometry is different. It is not clear from your post which counter will not fit your bike.

Tom and I have not figured out how to make one counter fit every bike, so we elected to go with a geometry that fits most bikes.

Payment methods will likely include Paypal,

Recent JO counters have a plastic gearbox. The geometry is different. It is not clear from your post which counter will not fit your bike.

Tom and I have not figured out how to make one counter fit every bike, so we elected to go with a geometry that fits most bikes.

Payment methods will likely include Paypal,

Some of the newer Cannondale mountain bikes use a really trick single-cylinder fork. Not really a fork, as it's only got one tube. This necessitates an unconventional wheel, but it also has a disc brake, which I'm sure interferes with the Jones.

http://www.cannondale.com/bikes/08/cusa/model-8VM3.html

Low-tech bikes are quite adequate for road-course measuring, but it's a shame to leave the good one in the garage.

http://www.cannondale.com/bikes/08/cusa/model-8VM3.html

Low-tech bikes are quite adequate for road-course measuring, but it's a shame to leave the good one in the garage.

After a bit of scrounging on the 'net, I find that the vast majority of axles I find as replacements will fit through the 10.5mm hole in the counter. There is one "Campy" axle that's bigger, but only one, and it's used on a Cannondale. Maybe others, but if so I didn't find them.

I have added a bit of extra "dish" to the assembly which will make the counter compatable with more of the big forks that are out there, but I don't think it is possible to make one that fits all possible configurations. It will fit the vast majority of road bikes, and I'd guess at least 70% of the mountain bikes I've looked at.

The counter may not fit some bikes with big, beefy forks, overly large hubs, disc brakes, etc. It may be that some bikes will allow it to mount on the rear dropouts as an alternate, but that isn't exactly ideal.

-------------

I've gotten to about 80% on the final shop drawings, but ran into a small snag I'll need to address before I order. Making slow, but good progress.

I have added a bit of extra "dish" to the assembly which will make the counter compatable with more of the big forks that are out there, but I don't think it is possible to make one that fits all possible configurations. It will fit the vast majority of road bikes, and I'd guess at least 70% of the mountain bikes I've looked at.

The counter may not fit some bikes with big, beefy forks, overly large hubs, disc brakes, etc. It may be that some bikes will allow it to mount on the rear dropouts as an alternate, but that isn't exactly ideal.

-------------

I've gotten to about 80% on the final shop drawings, but ran into a small snag I'll need to address before I order. Making slow, but good progress.

Fabio:

The obvious solution to your problems is to use an electronic counter.

The obvious solution to your problems is to use an electronic counter.

Yes, the electronic counter does work, but it has it's problems also. What Tom is doing is great. We should encourage Tom!!!

The electronic counter is an alternate to the Jones Counter concept and that's good. Tom is working to find another solution for us all. The fact that it doesn't work on all types of bikes is not a real problem as far as I'm concerned. My reason is simple - Most people don't use these high tech bikes to measure!

As stated before - Tom thanks for your efforts and I thank you.

The electronic counter is an alternate to the Jones Counter concept and that's good. Tom is working to find another solution for us all. The fact that it doesn't work on all types of bikes is not a real problem as far as I'm concerned. My reason is simple - Most people don't use these high tech bikes to measure!

As stated before - Tom thanks for your efforts and I thank you.

Hello to everybody, here some details about the problem I had to mount JOL (the one with metal gear).

The major problem is related to the assemply wheel's hub / fork.

The space to host the JOL is not enough, only 4.5 mm, if I insert the JOL I'v not anymore place for the fork.

And also to space between the JOL and the spoke is too large, no contact with the JOL gear.

I've try to enlarge the hole of the JOL in order to install it more closer to the spoke, but then the gear guide was disassemby, there was friction to the hub, and also contact to the fork.

This was with my road bike. Was worse with my MTB.

At the end I try with a low cost MTB of my sister and then, with some small modification, the JOL work fine.

As Stu Rigel say, low-tech bikes are quite adequate for road-course measuring, but it's a shame to leave the good one in the garage :-) or to buy a new bike (or only a new wheel) only because we can't mount the counter.

Electronic counter could be a nice solution when it will be accepted as measuring device, this means that must be solved also the back and forward counting.

(I've also a GPS Garmin EDGE 305 mounted, to combine with the JOL measure)

Nice solution could be the "hybrid" with electronic display (i.e.

Veeder-Root A103-001) and mechanical gear. But remain the problem of mounting in some bikes.

In any case, I think you are in the good direction to develop a new counter.

If my input can help you, I don't know, eventually we can furthermore develop a new version of the counter after the release of the next generation you are developping now.

Regards,

Fabio

The major problem is related to the assemply wheel's hub / fork.

The space to host the JOL is not enough, only 4.5 mm, if I insert the JOL I'v not anymore place for the fork.

And also to space between the JOL and the spoke is too large, no contact with the JOL gear.

I've try to enlarge the hole of the JOL in order to install it more closer to the spoke, but then the gear guide was disassemby, there was friction to the hub, and also contact to the fork.

This was with my road bike. Was worse with my MTB.

At the end I try with a low cost MTB of my sister and then, with some small modification, the JOL work fine.

As Stu Rigel say, low-tech bikes are quite adequate for road-course measuring, but it's a shame to leave the good one in the garage :-) or to buy a new bike (or only a new wheel) only because we can't mount the counter.

Electronic counter could be a nice solution when it will be accepted as measuring device, this means that must be solved also the back and forward counting.

(I've also a GPS Garmin EDGE 305 mounted, to combine with the JOL measure)

Nice solution could be the "hybrid" with electronic display (i.e.

Veeder-Root A103-001) and mechanical gear. But remain the problem of mounting in some bikes.

In any case, I think you are in the good direction to develop a new counter.

If my input can help you, I don't know, eventually we can furthermore develop a new version of the counter after the release of the next generation you are developping now.

Regards,

Fabio

Fabio,

Thanks for posting the well formatted pics of your problem. I'm not sure, but the modifications I've made to the geometry may allow it to mount to your road bike. I've increased the dish by 2mm, and increased the fork clearance from the JO model by 5mm. The conflict I see is with the cap on the hub. I may only need to increase the diameter of the cup a couple mm to solve the conflict.

I've never seen a cap like that on a hub before. Is it a rubber/plastic piece that can be easily removed? ie. a "beauty ring"? Does it seal in grease, or just add a streamlined look to the axle?

What is the diameter? I scaled it off the picture at 19mm, but this should clear the existing counter you have. Since it doesn't, I'll need some sort of direct measurement.

I'll see about going to a bike shop this weekend, they might have one I can look at.

Thanks again for posting the pics! I'll see what I can do.

Best,

Tom

Thanks for posting the well formatted pics of your problem. I'm not sure, but the modifications I've made to the geometry may allow it to mount to your road bike. I've increased the dish by 2mm, and increased the fork clearance from the JO model by 5mm. The conflict I see is with the cap on the hub. I may only need to increase the diameter of the cup a couple mm to solve the conflict.

I've never seen a cap like that on a hub before. Is it a rubber/plastic piece that can be easily removed? ie. a "beauty ring"? Does it seal in grease, or just add a streamlined look to the axle?

What is the diameter? I scaled it off the picture at 19mm, but this should clear the existing counter you have. Since it doesn't, I'll need some sort of direct measurement.

I'll see about going to a bike shop this weekend, they might have one I can look at.

Thanks again for posting the pics! I'll see what I can do.

Best,

Tom

Add Reply

Sign In To Reply