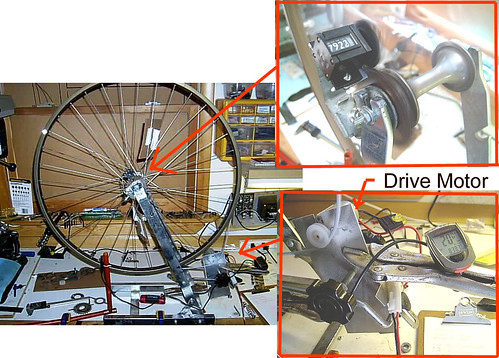

The Test Rig

I'll do a writeup when it's over, but looking good so far. I'm running at 190 rpm at the wheel, and the cyclocomputer makes it right at 20 mph. 9 hours in. I should have caught up to your counter by morning, if I can get any sleep with the thing running. The aluminum plate I used to mount the motor is ringing like a bell. I attached the vice-grips to dampen it, but it isn't exactly 100% effective.

So far, the only sign of wear is very small "leaflets" that grew from the plastic gear teeth at about 5 hours in. They have since worn off, and all is smooth.

More from Tom 29 September

I'm at it again. 350 miles yesterday, I'm shooting for 500. I ended up turning it off at 12:30 AM to get some sleep. It's so noisy, I'm hesitant to even move it outside. If the test goes longer (and it may for the final rig) I'll move it into the cabana (Tom's backyard toolshed). Think of an electric drill running, that's about what I'm dealing with.

Only very minor wear on the plastic gear, still no additional wobble on the metal one. No lube at all. I'll dis-assemble it and re-measure the inner diameter at the end. It started at 24.75mm for the hole, 24.65+/- on the retainer cup.

I'm short on time at the moment to get the production docs together for the fabricator, but I think I can get something together by next (not this) Monday. The 3D rendering is fine, but I'll need orthogonal views that call-out the specifics, and where they can take liberties.

While I think I want to keep the name "Jones counter", "the totalizer" has a nice ring to it.

I gotta go outside, this thing is driving me mad.