Jay:

You omitted to say that after a long overshoot correction with the Jones you have recalculate all future targets.

The only electronic counter you have tested is the $7 Bell -- the Protege and Totalizer are much easier to use.

I guess I'm so accustomed to having a unit that will not reset itself that it doesn't bother me to change a few digits if I make an error. That's why I will generally stop my errant path at a multiple of 500 counts- so I don't need to change the last three digits of what I've calculated.

A far more common occurrence, at least for me, than going off course, is overshooting my point by a couple hundred counts. I like being able to simply back up the bike for a few revolutions of the front wheel, and a counter that is capable of doing that will work better for me. Having to switch the counter to another mode to have it count backwards means you'd have to switch it again to make it count forward again, which is one more thing to have to remember to do.

I'd take a look at the Totalizer if I had a better idea of exactly how it worked. At this point, however, I'm not convinced that using a cyclocomputer of any kind is a superior method than using a mechanical counter like the Jones Counter.

A far more common occurrence, at least for me, than going off course, is overshooting my point by a couple hundred counts. I like being able to simply back up the bike for a few revolutions of the front wheel, and a counter that is capable of doing that will work better for me. Having to switch the counter to another mode to have it count backwards means you'd have to switch it again to make it count forward again, which is one more thing to have to remember to do.

I'd take a look at the Totalizer if I had a better idea of exactly how it worked. At this point, however, I'm not convinced that using a cyclocomputer of any kind is a superior method than using a mechanical counter like the Jones Counter.

I don't agree with Duane that there a just a few that don't like the idea of the electronic counter. I have seen first hand that a new measurer with the help of an experience measure did not set up the bike properly and got real bad results. The JO counter is a nobrainer and your least likely to make a mistake when doing the math. Again, I'm not saying this totalizer is a bad idea, but I believe you still have to set up the rim and it's easy for some but a lot of people just don't get how it's done.

I would suggest to Neville that sometime in the spring that we have a couple of workshops on the electronic counter. Neville if interested please contact me via email.

I would suggest to Neville that sometime in the spring that we have a couple of workshops on the electronic counter. Neville if interested please contact me via email.

Jay:

With the superior display of the Protege and the Totalizer and the fact that unlike with the Jones you are always looking for the same standard numbers means that you are less likely to overshoot.

With the superior display of the Protege and the Totalizer and the fact that unlike with the Jones you are always looking for the same standard numbers means that you are less likely to overshoot.

Gene:

I will post a simlified method for very accurately marking the rim in decimals that takes only 5 or 10 min.

I will post a simlified method for very accurately marking the rim in decimals that takes only 5 or 10 min.

I have used the JO from Day 1. I like it. It works fine, until it doesn't. I have owned 3. One was the newest version from Paul. While the new mount works on some bikes, it worked on neither of mine, even with modifications, so I returned it. Paul was kind enough to give me a full refund, in spite of my modifications.

While on a measurement, my co-measurer (marathon course) had his counter torque and freeze. Able to get it functional, but when will it torque again, and die? I loaned him my backup for some courses he measured.

My Unit #1 gave me nasty disparities on each leg of my calibration course, which seems to indicate internal gears shot, as it gave me approx 1000, plus and minus 200, additional counts for each leg. Unit is worthless.

My backup was loaned-out due to another JO malfunctioning. I have nothing, and my only source had a product I can't use. My business could fail, due to no counter. Fortunately, I was able to get my loaned-out counter back that day.

I have ordered a Totalizer, and will report to all how it works. Necessity is the mother of open-mindedness, to paraphrase.

When the new Super Duper Riegal Slooper is available, I will order at least one of them, also. I do over 30 courses a year, and can't afford to be without at least two counters. (I backup all my computer files, also)

Thank you, Neville, for offering an alternative product for our "profession".

While on a measurement, my co-measurer (marathon course) had his counter torque and freeze. Able to get it functional, but when will it torque again, and die? I loaned him my backup for some courses he measured.

My Unit #1 gave me nasty disparities on each leg of my calibration course, which seems to indicate internal gears shot, as it gave me approx 1000, plus and minus 200, additional counts for each leg. Unit is worthless.

My backup was loaned-out due to another JO malfunctioning. I have nothing, and my only source had a product I can't use. My business could fail, due to no counter. Fortunately, I was able to get my loaned-out counter back that day.

I have ordered a Totalizer, and will report to all how it works. Necessity is the mother of open-mindedness, to paraphrase.

When the new Super Duper Riegal Slooper is available, I will order at least one of them, also. I do over 30 courses a year, and can't afford to be without at least two counters. (I backup all my computer files, also)

Thank you, Neville, for offering an alternative product for our "profession".

Another alternative is the chain drive counter.

I recently dismounted and inspected mine. It had accumulated 586 km - 364 miles - and absolutely no wear was visible under high magnification. The delrin chain and gear looked brand new.

It's cheap, operates exactly as a Jones Counter should and is readable from left to right.

I recently dismounted and inspected mine. It had accumulated 586 km - 364 miles - and absolutely no wear was visible under high magnification. The delrin chain and gear looked brand new.

It's cheap, operates exactly as a Jones Counter should and is readable from left to right.

Neville,

While my example may have been farcical, I like to take examples to their extreme, because it is often easier to understand what's going on. It worked for me because I now understand how it works. I think it helped Duane understand as well.

My main issue with electronic counters is that I would always worry that the magnet missed a count, or that somewhere on the course I backed over the magnet to get an extra count. I would always want to use my Jones as a backup to make sure that didn't happen. But if I'm always going to use my Jones in addition to the electronic counter, what's the point of using the electronic counter?

But I can now see how I could use it to make life simpler. As I'm measuring the course I could completely rely on the electronic counter to take measurements, backtrack on the course, reset to zero when needed, etc. But as I'm doing all of this I would keep records of every Jones count along the way. I just wouldn't do any calculations with them or use them to make any decisions. When I get home I could go through the fairly complicated process of using the Jones count record that I took to make sure there were no issues with the electronic counter measurement. If there were, I would have to go back out to the course to make corrections, but I expect that's not going to happen often, if ever.

While my example may have been farcical, I like to take examples to their extreme, because it is often easier to understand what's going on. It worked for me because I now understand how it works. I think it helped Duane understand as well.

My main issue with electronic counters is that I would always worry that the magnet missed a count, or that somewhere on the course I backed over the magnet to get an extra count. I would always want to use my Jones as a backup to make sure that didn't happen. But if I'm always going to use my Jones in addition to the electronic counter, what's the point of using the electronic counter?

But I can now see how I could use it to make life simpler. As I'm measuring the course I could completely rely on the electronic counter to take measurements, backtrack on the course, reset to zero when needed, etc. But as I'm doing all of this I would keep records of every Jones count along the way. I just wouldn't do any calculations with them or use them to make any decisions. When I get home I could go through the fairly complicated process of using the Jones count record that I took to make sure there were no issues with the electronic counter measurement. If there were, I would have to go back out to the course to make corrections, but I expect that's not going to happen often, if ever.

Mark:

I was not criticizing you for using a farcical example.

Like you I was cautious about accepting the electronic counter, and road many hundreds of miles and measured several courses using several of them with the Jones simultaneously. Your plan to use an electronic counter simultaneously with the Jones makes sense except that I would only read the Jones on one continuous ride of the course. Immediately afterwards, I would multiply the electronic reading by the gearing of your particular Jones (cts/rev) and check that this is identical to the net Jones count. In time you may acquire the confidence to dispense with this check.

I was not criticizing you for using a farcical example.

Like you I was cautious about accepting the electronic counter, and road many hundreds of miles and measured several courses using several of them with the Jones simultaneously. Your plan to use an electronic counter simultaneously with the Jones makes sense except that I would only read the Jones on one continuous ride of the course. Immediately afterwards, I would multiply the electronic reading by the gearing of your particular Jones (cts/rev) and check that this is identical to the net Jones count. In time you may acquire the confidence to dispense with this check.

NEW COUNTER UPDATE

Tom has completed 16 designs so far. Each time one gets done we find some problem we had not addressed. The biggest one is adequate clearance between fork, wheel and counter. The last one, #16, looked promising but we are thinking about going back to #12 and developing it further. While it is tempting to say “it will be just another week before we are ready” it’s too much like crying wolf.

Each time we decide to make a final change it seems to add a week, since Tom works full time, and the drafting of each new design takes up lots of his free time. The design will be done when it’s done.

Once we have a final design we will work with the fabricator to see whether they can make it as we have it designed. They will give us a quotation for fabrication, and a delivery time. We expect the tooling cost to be several thousand dollars, and the cost per drive unit to depend on how many we order. This is why it is taking longer than we would like. We must get it right the first time. While it only exists on paper we can change it – once we have 500 or a thousand on hand we are stuck with them, so they had better be right. Once we give the fabricator a check and the go-ahead it will be about two months before we will receive any drive units. Most of this time will be spent by the fabricator in design and construction of the stamping/punching tooling.

We’ll receive a few pre-production units and will check them out before approving delivery of the full order.

There has never been a counter which fits 100 percent of all bicycles. Ours will be no exception. We are striving for a design which will fit at least as many as did the original Jones, and the earlier JO’s.

Where do we stand? We’re working on it and, as usual, we think it will be a week or so before we contact the fabricator. Updates will appear from time to time.

Tom has completed 16 designs so far. Each time one gets done we find some problem we had not addressed. The biggest one is adequate clearance between fork, wheel and counter. The last one, #16, looked promising but we are thinking about going back to #12 and developing it further. While it is tempting to say “it will be just another week before we are ready” it’s too much like crying wolf.

Each time we decide to make a final change it seems to add a week, since Tom works full time, and the drafting of each new design takes up lots of his free time. The design will be done when it’s done.

Once we have a final design we will work with the fabricator to see whether they can make it as we have it designed. They will give us a quotation for fabrication, and a delivery time. We expect the tooling cost to be several thousand dollars, and the cost per drive unit to depend on how many we order. This is why it is taking longer than we would like. We must get it right the first time. While it only exists on paper we can change it – once we have 500 or a thousand on hand we are stuck with them, so they had better be right. Once we give the fabricator a check and the go-ahead it will be about two months before we will receive any drive units. Most of this time will be spent by the fabricator in design and construction of the stamping/punching tooling.

We’ll receive a few pre-production units and will check them out before approving delivery of the full order.

There has never been a counter which fits 100 percent of all bicycles. Ours will be no exception. We are striving for a design which will fit at least as many as did the original Jones, and the earlier JO’s.

Where do we stand? We’re working on it and, as usual, we think it will be a week or so before we contact the fabricator. Updates will appear from time to time.

Your plan to use an electronic counter simultaneously with the Jones makes sense except that I would only read the Jones on one continuous ride of the course.

Continuous rides are not what I'm concerned about. Stopping, starting, backtracking, etc. is where I'm afraid I'll mess something up and add/subtract an extra revolution. I wouldn't feel comfortable relying on the electronic counter without a Jones count record of the entire measuring process to confirm, at least the first few times.

Continuous rides are not what I'm concerned about. Stopping, starting, backtracking, etc. is where I'm afraid I'll mess something up and add/subtract an extra revolution. I wouldn't feel comfortable relying on the electronic counter without a Jones count record of the entire measuring process to confirm, at least the first few times.

quote:Originally posted by Tom Riegel:

I'm working on a new counter based on the metal gear we've used for years, with a minor modification to aid in assembly. Cost should come in on-par with the old ones.

I've contacted a number of prototyping companies to see if they would be interested in producing the metal gear assembly. Most said they would not be interested because of the highly complex nature and low volume of the pieces.

One manufacurer has expressed an interest, and I sent him my counter to evaluate. I expect an estimate to produce 300 gears sometime in mid-August. Production time will be determined then.

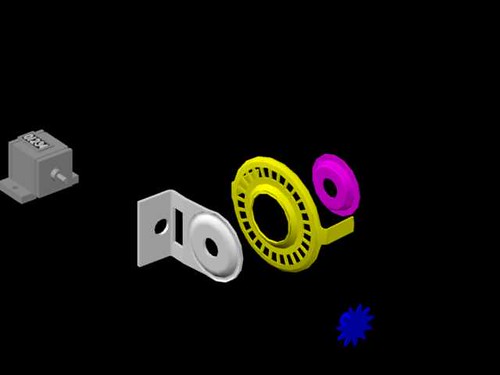

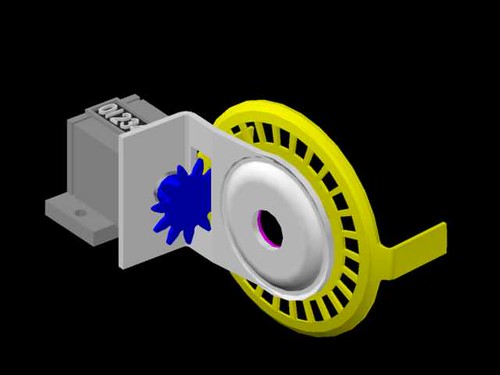

The counter I'm proposing will have an identical ring gear (yellow) and retainer cup (magenta) and a modified baseplate (white).

The remaining gear (blue) should be easy to obtain in low volumes. I need to look into that. My hope is to have all the pieces available in a couple months if the price is right.

Tom,

I suggest you ask Justn, Jane or katz for their input as to who will try your new counter. The BB us not the best source for finding active measurers.

Regards,

Gene

I suggest you ask Justn, Jane or katz for their input as to who will try your new counter. The BB us not the best source for finding active measurers.

Regards,

Gene

Add Reply

Sign In To Reply