One hopes that Paul Oerth will be successful in locating a source for gear drives for Jones/Oerth counters. We will be happy if he does.

Should the hunt be unsuccessful we will have to find something else. The present design is universal in its mounting – it fits almost all bikes. The mounting method is quite effective.

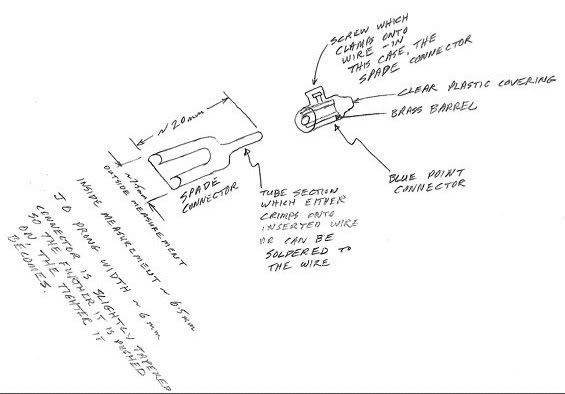

It could be that an effort will have to be made to make dies to punch out the three main parts of the drive. If this must happen, the design can be modified to simplify construction. Below is one way to do it. This is a crude first concept, not a solid proposal. I put it forth hoping to stimulate discussion.

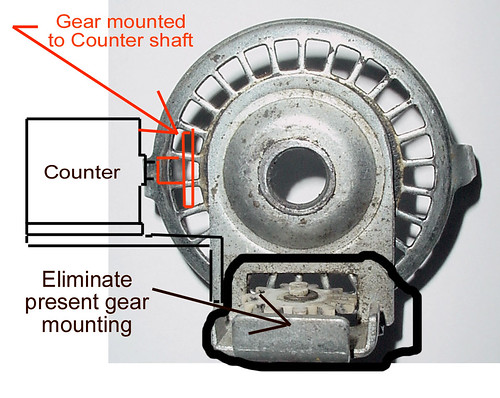

The new design eliminates the present plastic gear and the brass machined sleeve in which it rotates, and also eliminates the white plastic adapter that mates the gear to the counter.

By using an off-the-shelf gear that mounts directly to the counter shaft, the shaft will not have to be squared off.

Let’s see some discussion. We have a problem!