January 21, 2008 - The counter project has three phases. The first, the design and development phase, is now complete. A small amount of redesign has been completed, and Tom and the fabricator have reached agreement about what Tom wants to be done and what the fabricator can do. The design work of the fabricator was paid for earlier. Questions of quantity and parts finishing have been decided. Tooling work has begun.

Phase two has now begun. A check was written yesterday for fabrication of 1000 units. Fabrication will begin as soon as the punching tools have been made, which is in progress. Estimated delivery is not known yet, but will be reported when we know something specific.

Upon delivery of the parts, phase three, assembly of the units by Tom, will begin and units will become available for sale.

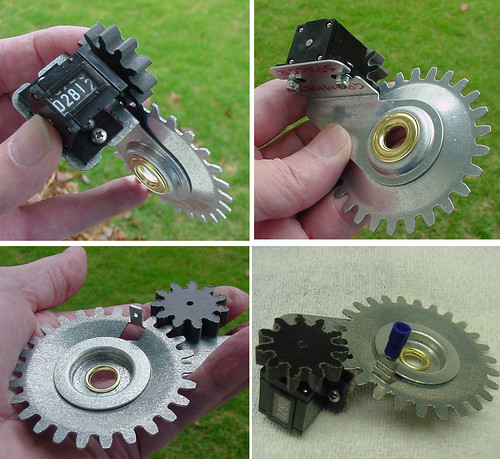

Original Post