I thought I would touch base with you on my experience with the Jones counter.

As discussed a while ago, I have been looking for a solution for the broken tangs and I now fit the Jones counter as shown on the attached. I have a wheel that is permanently fitted with the Jones counter that I just keep for measuring...this wheel is perfectly trued, has axle exposed on both sides for the fork to sit on and no more problems with the Jones counter breaking for nearly 12 months now.

I have another wheel that I use on the same bike for normal riding. I have given the attached fitting instructions to Dave Cundy for distribution to the other Aussie measurers.

JONES COUNTER IDEAL FITTING INSTRUCTIONS

(Based on the current Jones Counter design as at June 2014)

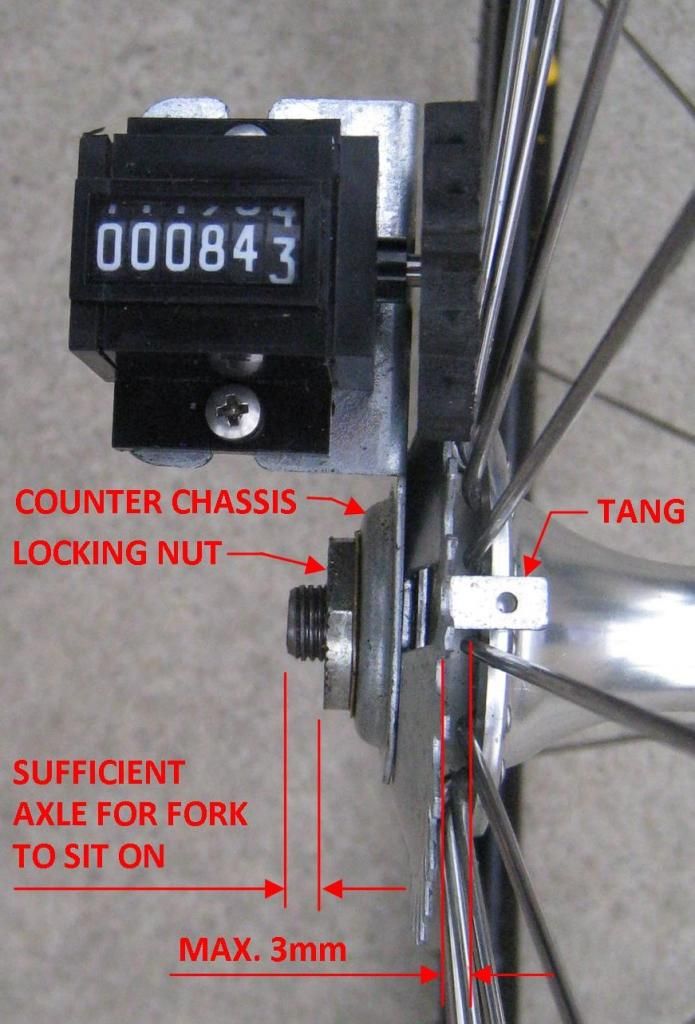

1. TO PREVENT THE TANG BREAKING, THE MAXIMUM DISTANCE FROM THE CHASSIS COG TO THE POINT OF CONTACT OF THE TANG ON TO THE SPOKE IS 3mm.

IF THE TANG EXTENSION IS REQUIRED, THEN COUNTER CHASSIS IS TOO FAR AWAY FROM THE POINT OF CONTACT ON THE SPOKE.

THIS MAY REQUIRE THE LOCKING NUT TO BE REMOVED.

2. FOR RIDING SAFETY, THE FORK MUST BE RESTING ON AT LEAST SOME PART OF THE AXLE ON BOTH SIDES.

3. THE IDEAL SETUP IS TO HAVE THE COUNTER CHASSIS POSITIONED BETWEEN THE LOCKING NUT AND THE AXLE CONE, THEN THE WHEEL CENTRED BETWEEN THE OUTSIDE OF THE LOCKING NUT ON BOTH SIDES (as shown above). THIS MAY REQUIRE ASSISTANCE FROM A BIKE MECHANIC.

IN THE ABOVE EXAMPLE, THE WHEEL HAS BEEN RADIALLY SPOKED WITH THE SPOKES PROTRUDING ON THE OUTSIDE OF THE HUB FLANGE RATHER THAN THE NORMAL WAY WHERE THE SPOKES PROTRUDE FROM THE INSIDE OF THE FLANGE (this also makes the wheel stronger but perhaps not as aesthetically pleasing). THE REASON FOR THIS IS TO REDUCE THE DISTANCE FROM THE PONT OF CONTACT WITH THE TANG AND THE SPOKE TO THE CHASSIS COG.

4. IDEALLY, THE COUNTER COG SHOULD FIT AS DEEP AS POSSIBLE INTO THE CHASSIS COG VALLEYS.

PLEASE NOTE THAT THESE INSTRUCTIONS ARE NOT FROM THE JONES COUNTER SUPPLIERS BUT DEVELOPED AS A POSSIBLE SOLUTION TO BROKEN TANGS.