I had to measure a marathon & half about a two hour drive from my home and no one willing to make the trip. Pete had come up with a method but I decided to re-invent the wheel (didn't research what he did).

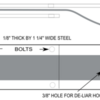

1.Screwed an eyelet into the end of a plank of wood approximately 4' x 8" x 1"

2. Placed the wood on the ground with the end about 6 inches from the start of the calibration course.

3. Drove one of the tires onto the blank.

4. Using a plastic tie, attached the end of the tape to the eyelet.

5. Place a piece of white tape (vinyl) under the end of the tape. Pulled the tape and marked the zero point.

6. Rolled out the tape, pulled, and marked the 100 meter point.

7. Rolled back the tape and checked that the zero point had not moved - it didn't. Cut the plastic tie, packed up and drove down to the 100 meter point.

8. Repeated the process with a new plastic tie. This allowed me to adjust the distance of the eyelet to the new zero point. I thought about leaving the tape attached to the eyelet when transporting but I thought the wood would shift a little when I drove up on it.

One snag: I was setting this up about 2 feet from a curb on a nice straight road. At the end of the first 100m segment there were leaves on the ground and it was too damp to hold the vinyl tape. Used my little retractable 12 foot tape and placed marks 4 feet from the curb (beyond all the leaves) every 5 meters along the entire 300m calibration course. Started from scratch.