"I have never heard of the counter failing."

That's a quote from Peter Riegel who's had about as much experience with counters as anybody, so it most be pretty unusual for counters to fail, but mine did. When it was about to turn over from 999999 to 000000, it didn't; instead, the last ring of numerals kept turning, but the others did not. I dissected the thing (purchased, I believe, in the early 1980s from the Joneses themselves) and didn't see an obvious problem that I could fix. Plus, I pretty much destroyed it taking it apart. The gear-drive parts seem fine, though.

David Reik

A description of what’s inside a counter may be found by downloading Measurement News #128 from www.rrtc.net.

Here’s a picture of a counter disassembled:

Here’s a picture of a counter disassembled:

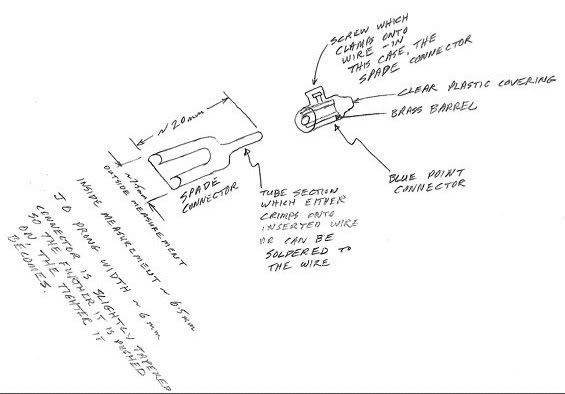

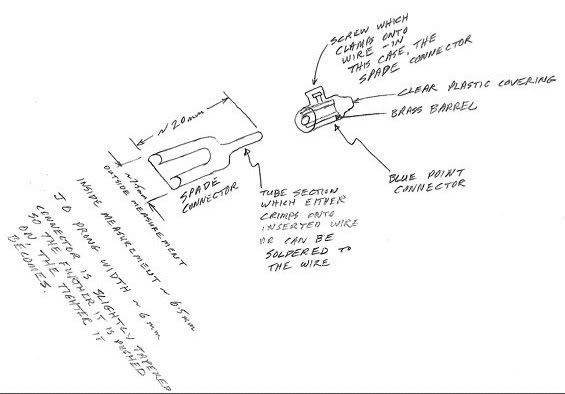

I've got a JO counter and have bent the engaging prongs back so they clear the spokes. I then made-up 2 adaptors - these are electrical spade connectors (used in cars and other electrical equipment) and the size I have is a tight fit onto the counter prongs. Onto the barrel part of this connector (the end that accepts the wire for soldering or crimping), I clamp a blue point connector to ewnlarge the adaptor. I can then cycle any distance with the counter mounted and slip-on either 1 or 2 adaptors to engage the spokes when I'm ready to measure. I then remove them to cycle home. Therefore my only counter wear and tear is when I'm actually measuring.

Geoff,

If you just slip them on, don't you worry about them coming off in the middle of a measurement?

Do you have any pictures?

If you just slip them on, don't you worry about them coming off in the middle of a measurement?

Do you have any pictures?

Mark,

Sorry, I don't have any photographs - I don't a digital camera. But if you really want some, I could impose on some friends to provide me with photos and send to you.

The term "slip them on" was just a figure of speech. The fit is quite tight, just like any electrical connection in a car (which if it were loose it would disengage from its spade terminal at the first bump in the road). The counter prongs are just like an electrical spade terminal. It needs a reasonable amount of push or pull to put it on or take it off. It really works a treat for me.

If you are not familiar with the blue point connectors, they are connectors we use in house wiring in Australia where you join cores of power cables in a plastic junction box. They are "floating" connectors. This connector fills-up most of the spare space between the spokes when the adaptor is installed on the counter.

Let me know if you want any photos.

Sorry, I don't have any photographs - I don't a digital camera. But if you really want some, I could impose on some friends to provide me with photos and send to you.

The term "slip them on" was just a figure of speech. The fit is quite tight, just like any electrical connection in a car (which if it were loose it would disengage from its spade terminal at the first bump in the road). The counter prongs are just like an electrical spade terminal. It needs a reasonable amount of push or pull to put it on or take it off. It really works a treat for me.

If you are not familiar with the blue point connectors, they are connectors we use in house wiring in Australia where you join cores of power cables in a plastic junction box. They are "floating" connectors. This connector fills-up most of the spare space between the spokes when the adaptor is installed on the counter.

Let me know if you want any photos.

Geoff sent me the drawing of the connectors that he used shown below

With that I was able to find the connector and install it on my counter as shown below

I was not able to find the blue point connectors Geoff talked about, so I just got a different connection that fit into the other end of the first connection. However, the first connection was long enough to engage the spokes so I left it at that. I rode a little bit with the connectors both on and off, and it worked just the way it was supposed to.

Thanks for the great idea Geoff.

With that I was able to find the connector and install it on my counter as shown below

I was not able to find the blue point connectors Geoff talked about, so I just got a different connection that fit into the other end of the first connection. However, the first connection was long enough to engage the spokes so I left it at that. I rode a little bit with the connectors both on and off, and it worked just the way it was supposed to.

Thanks for the great idea Geoff.

Add Reply

Sign In To Reply